SPECIAL STAINLESS REINFORCEMENT STEEL FOR STRUCTURAL DESIGNS

Opening possibilities for aesthetics and impeccable fair faced concrete

Since the beginning of the 1950ies, fair faced concrete has become a stylistic element. With a focus on the honest, visible use of materials fair faced concrete has become a synonym for a raw, yet sensual architecture. Following the visions of architects for the realization of residential buildings, concert halls, stadiums or parks place extremely high demands on the construction industry: they have to be long-lasting, safe and flawlessly beautiful. With the use of the optimal reinforcement steel, building contractors’ wishes and architects’ creative visions can become reality.

How to avoid corrosion risk and achieving durability

Challenge: Overcome limitations due to carbonation induced corrosion

There is virtually no limit to design and structural possibilities, when reinforced concrete is used. In the past, however, there was one big but: Because the cement stone reacts with the CO2 in the air, causing the pH-value of the concrete pore water to decrease, the corrosion protection of the normal reinforcement is lost over time and thus begins to corrode. The resulting corrosion products initially cause cracks (possibly accompanied by rust plumes) and later concrete spalling, and finally, reduces the bearing capacity. Usual relatively high concrete coverings usually require large-sized and thus heavy components

The solution: Finding the balance between durability and aesthetics

Today, with the use of reinforcement steel with a higher corrosion resistance, slender constructions or applications with a greater risk for cracking, have become possible. Thanks to the higher corrosion resistance of the steel, exceedingly thick concrete coverage has become obsolete. The minimal concrete cover not only has advantages from an aesthetic point of view, but also means that less concrete and thus less construction weight is required, which reduces transport and handling costs.

| Exposure | Environmental influences | Reinforcement cover Cnom | ||||||||

| Regular steel | Top12, DE | Top12, CH | ||||||||

| XC1 | Dry or always wet | 20 mm | 20 mm | 20 mm | ||||||

| XC2 | Wet, seldom dry | 35 mm | 30 mm | 20 mm | ||||||

| XC3 | Moderately damp | 35 mm | 30 mm | 20 mm | ||||||

| XC4 | Alternating wet and dry | 40 mm | 30 mm | 20 mm | ||||||

When using Top12, additional reductions may be made compared to the values in the table for B500B according to DIN 488 / SIA 262 in accordance with the building authority approval (DE) or SIA 2029 (CH).

When is the use of stainless steel recommended?

Using stainless steel reinforcement makes sense, when the structures face one or several of the following challenges:

- Reduced reinforcement cover

- Danger of corrosion due to crack formation

- Difficult execution or fluctuating execution quality

- Targeted long lifespan

Ideal applications for stainless rebar

In order for residential structures to be aesthetically attractive while remaining economically sensible, deciding precisely where and which type of stainless steel to use is crucial. The principal applications for stainless steel in residential structures are:

- Precast concrete components

- Sandwich panels

- Architectural concrete

How to merge high static requirements and light architectural design

Challenge: Meeting high static requirements

Architectural and structural design should not be limited by the properties of the materials used. In reality some constructions, such as heavy duty columns or wide stretched ceilings, have to withstand great high static forces. This normally calls for thicker constructions, leading to a lesser space utilization or even making certain constructions impossible.

The solution for Switzerland: Using higher strength reinforcement

With the use of higher strength steel, such as the Top700, which is only available in Switzerland, streamlined designs and slimmer constructions become possible. Thanks to the yield strength of more than 700N/mm2 the percentage of steel in concrete can be reduced and very high strength can be guaranteed – right up to earthquake-proof structures. While no special concrete properties are required, using higher strength reinforcement steel allows the reduction of steel used by up to 40%. Resulting in lower steel need and lesser transport. The environment says thank you.

Applications for higher strength steel rebar (not stainless)

The principal application for higher strength steel reinforcement in residential structures are:

- earthquake-proof applications

- heavily reinforced components

- precast concrete components

- columns

- warehouses

Technical performance standards for seismic areas

In the course of the new European laws on earthquake construction (Eurocode 8), an update of the legal seismic zones in France was also carried out in 2010.

Seismic zoning in the example of France

These new seismic zones required an adaptation of the construction method in consideration of new parameters. One of the solutions for the reinforcement of concrete structures is the use of stainless reinforcing steel. Thanks to its higher mechanical strength, cold-formed reinforcing steel perfectly meets the structural requirements for buildings.

UGIGRIP® as stainless reinforcing steel with outstanding mechanical properties

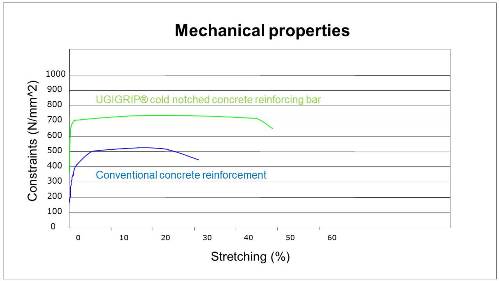

The three main grades of UGIGRIP®, thanks to their duplex structure and cold notching, guarantee a level of mechanical characteristics adapted to the new regulations.

Stainless reinforcing steel for infralight concrete

100% corrosion protection despite expected carbonation

Credits:

Architect: KPT Architekten, www.kpt-architekten.de

Photos: Mattias Richter, www.mattiasrichter.com